Technical Data

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Fluids & Lubricants Features

- Product Features

- Corrosion inhibitor in aqueous systems at pH ≥ 7

- Corrosion protection in aerosol cans

- Approved for use as inerts in non-food pesticide formulations

- Hard water stability

- Biodegradable

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Coating End Applications

- Fluids & Lubricants End Use

- Industrial Additives End Use

Properties

- Physical Form

- Soluble In

- Appearance

- Clear to hazy viscous liquid

- Soluble in

- Water, Glycols

- Insoluble in

- Oils, Alcohols, Solvents

- Typical Properties

Value Units Test Method / Conditions Activity approx. 100 % Density (at 25°C) approx. 1.15 g/mL Specific Gravity (at 25°C) approx. 1.15 - Specifications

Value Units Test Method / Conditions Color max. 2 Gardner pH Value (1% in Distilled Water) 9.3 - 10.3 - - Alkali Value 570 - 600 mg.KOH/g - - Solubility Data

Value Units Test Method / Conditions Water (wt. 10%) Complete - -

Technical Details & Test Data

- Corrosion Testing Using Decore Be

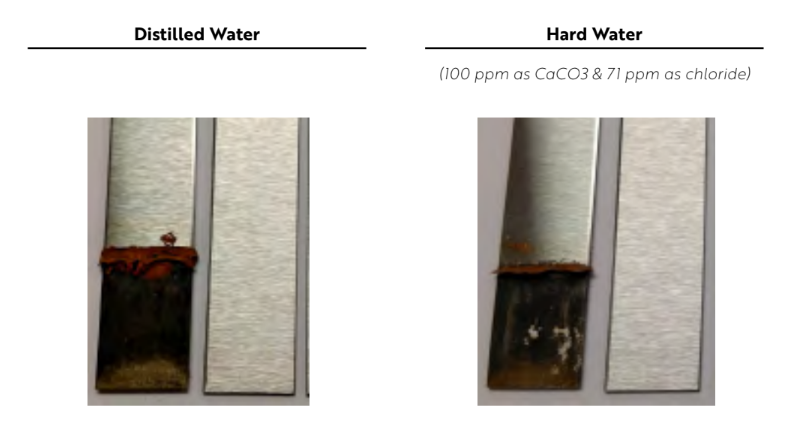

- Metal Panel Submersion Test

- DeCORE BE was tested at 0.5% by weight in hard water and/or distilled water on cold rolled steel panels for six months.

- The bottom half of the metal panels were submerged in the test solutions.

- The top half of the panels were exposed to the vapor phase. Panels on the left did not contain inhibitor.

Steel Panels: Sae 1010 Cold Rolled Steel (Mild Carbon)

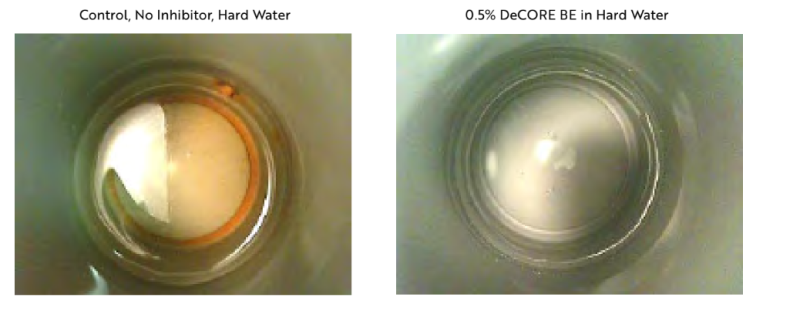

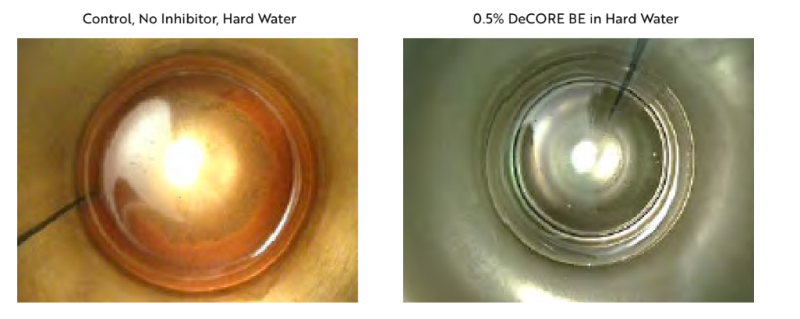

Corrosion Testing In Aerosol Cans

Grey Lined, Tin Plate Cans (AAC-7809 McKernan Packaging)

Unlined, Tin Plate Cans (AAC-8001 McKernan Packaging)

Packaging & Availability

- Regional Availability